WHERE SKILL SUCCEEDS IMAGINATION

We are the go-to team for precision engineering in Southland.

Suppling our services to all of NZ and abroad, our specialist machine workshop manufactures metal and plastic componentry for industry and is one of the largest and most sophisticated in the South. We excel at designing innovative solutions for customers that drive efficiencies within their business. As well as manufacturing one off bespoke design parts, we also have the capability to churn out products by the thousands.

Some of our customers include New Zealand Aluminium Smelters, Alliance Group, Dongwha New Zealand, Fonterra, Prime Range Meats and many other manufacturing and engineering companies that can’t do what we do. We also supply to a range of other industries, including tourism operators, aircraft, marine, forestry and just about any other industry you can think of as well as exporting some of our products to Australia and China.

We believe in building strong relationships with our customers to really understand their engineering requirements so we can modify, design and manufacture to suit the application required.

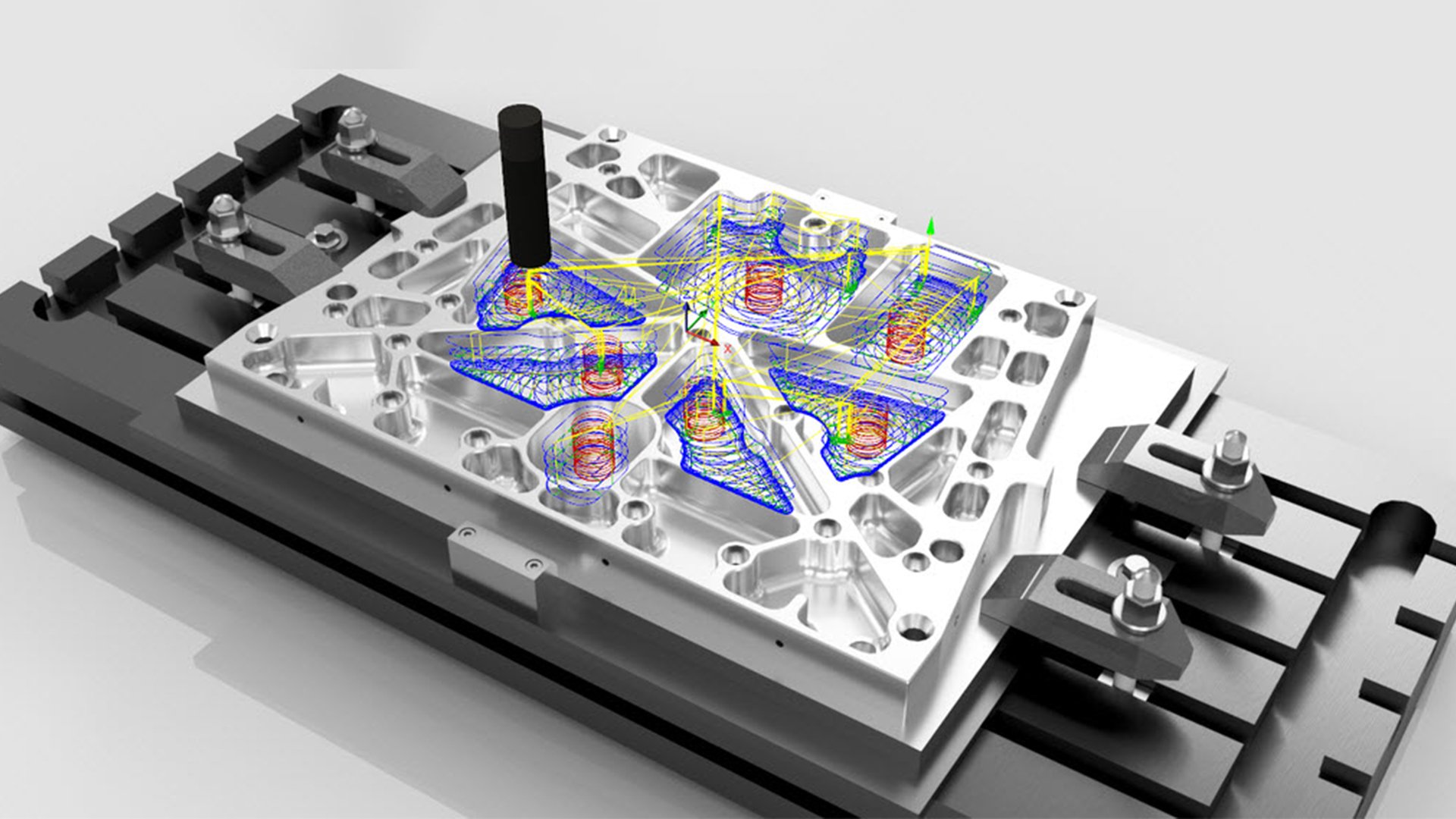

The increasing applications of our Computer Numerical Control (CNC) milling, turning and laser cutting technology, with potential to produce very small or very large products, allows us to deliver significant benefits including labour savings to customers across a wide range of sectors.

Think axles, pins, shafts, gears and cogs for starters - we say “For starters” because we like to think that anything’s possible and MPE can machine just about anything.

On any given day, we might be working on giant steel grabbing claws for heavy industry, a valve bank replacement, a new chain for a meat processor or designing and executing a solution to a complex problem.

Or we might be completing a smaller precision engineering task for a general engineering company or backyard car or aircraft enthusiast.

We re-engineer components where necessary to make them even better.

We’re there for you when something breaks, with repair and maintenance staff on deck to get you up and running again as fast as possible.

MPE is the best equipped, dedicated, precision engineering workshop in Southland using the latest in CNC equipment in conjunction with traditional lathes, mills and welding equipment.

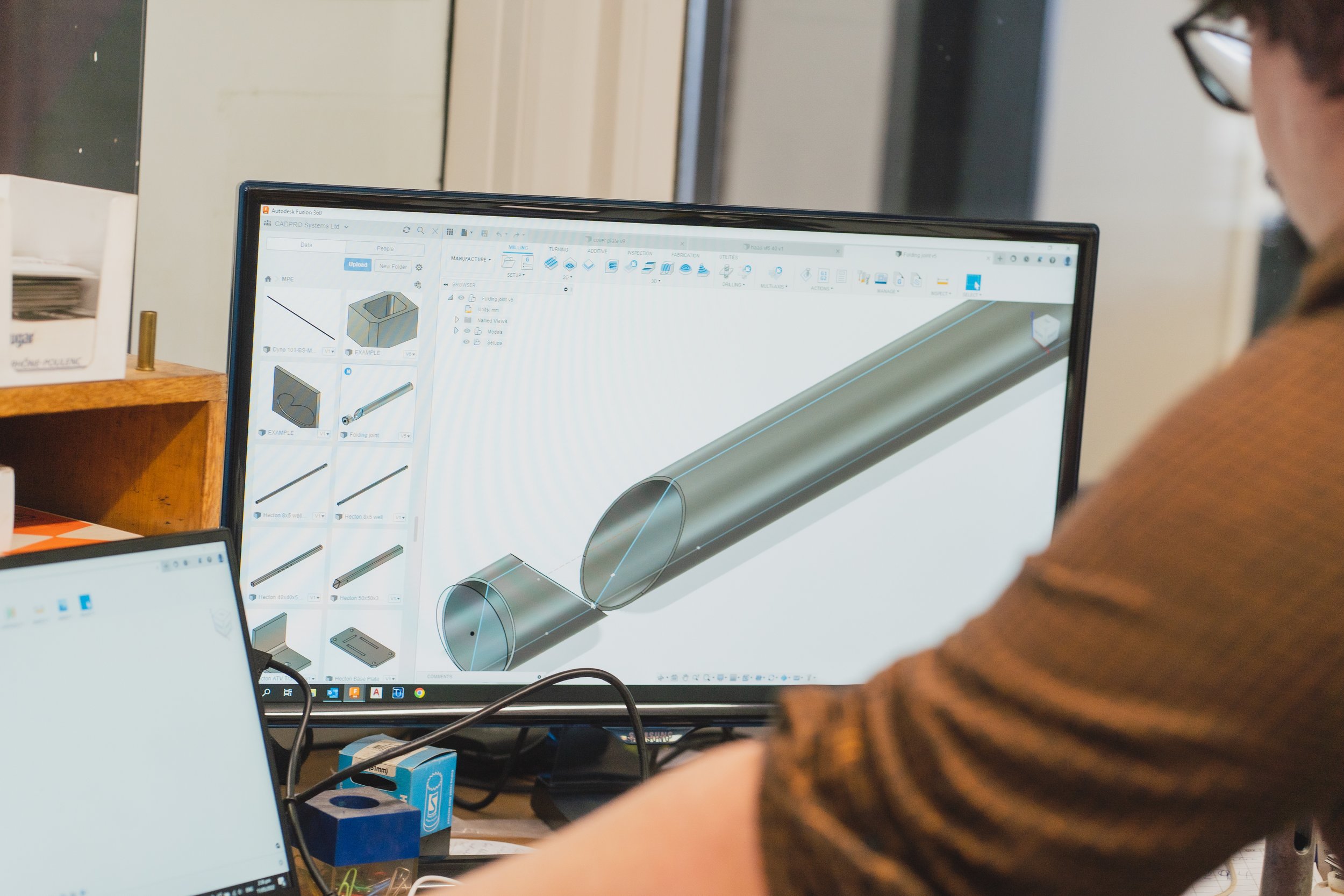

CNC Tube & RHS Laser Cutter

New to MPE in 2022 our CNC hollows laser is re-imagining the way hollow sections are processed. Laser cutting flat plate and sheet is not new to the south but being able to now process pipe, tube, box section and other various profiles with our CNC laser is changing the face of manual fabrication and manufacturing as we know it. Speeding up production times and reducing cost for our clients is the biggest benefit along with the precision tolerances it achieves makes this a no brainer.

Our CNC laser cutter has the ability to cut pipe, tube, RHS, angles, and other bespoke sections. This machine makes light work of cutting mild steel, aluminium, and stainless metals efficiently and accurately every time, thanks to its tight tolerance capabilities.

Victor CNC lathes

Both of our Victor CNC lathes are ideal for one off bespoke parts or large production runs. They have an extremely fine tolerance and can perform multiple operations in the one programme, meaning faster turnaround for you.

V-Turn II26 – 3 axis standard CNC lathe with 370mm diameter maximum capacity in the chuck and 70mm diameter up the spindle with 620mm between centres.

V-Turn A26Y – 4 axis CNC lathe complete with live tooling for additional milling and turning capability. 370mm diameter maximum capacity in the chuck and 70mm diameter up the spindle with 1400mm between centres.

HAAS CNC MILLS

Haas Automation is the largest machine tool builder in the United States, and one of the largest builders of CNC machines in the world. And they have the technology to match – that’s why we partner with them. They are one of the highest performance machines available today and we have 2 Haas CNC mills, a VF3 and larger VF6 complete with 4th axis powered dividing head.

VF3 - X axis 1016mm, Y axis 508mm, Z axis 635mm, maximum weight on table 1,588kg

VF6 - X axis 1626mm, Y axis 813mm, Z axis 762mm, maximum weight on table 1,814kg

Manual Machines

MPE has 4 manual lathes and 2 turret manual mills to cater for the manual turning, milling and slotting (internal keyways), along with also having a horizontal borer that is idea for those larger jobs that or a bit outside the norm.

GRINDING

Cylindrical Grinder – Able to grind up to 250mm dia 600mm long

Surface grinder – Able to grind up to 200mm wide 400mm long

GEAR HOB

We have our own gear cutting hob. Using specialist cutters we can readily produce gears both straight cut and helical along with splines. We have most metric cutters and a good selection of imperial cutters, and commonly cut both metal and plastics.

HEAT TREATMENT

We’ve operated a cyanide salt furnace for through hardening and case hardening metal objects for more than 30 years. Finished results vary depending on metal type, furnace emersion time and various tempering options offered. Most grades of steel can be hardened in the pot and we also have two tempering ovens which can reach temperatures of over 600 degrees Celsius.

METAL SPRAYING

We’ve been metal spraying for 20 years. We have a variety of options available for our customers including steel, stainless steel, titanium, and ceramics. Most shafts eventually wear around bearing and seal positions, and MPE can restore these at a fraction of the cost of a new shaft in most cases. We operate both wire and powder-spray equipment to give our customers the best solution.

WELDING & FABRICATION

We have the expertise and equipment to perform general fabrication repairs on used equipment as well as fabricating new products for ourselves or our clients. Utilising MIG, Arc and Tig welding we can weld many different types of metals and have invested in good gear so we get a quality result every time.

OTHER SERVICES OFFERED

CAD/CAM (Computer Aided Design & Manufacturing)

Design work and problem solving

3D Scanning ability for geometry capture, reverse engineering, condition monitoring & inspections

3D Printing services available on application